Our company’s relocation,transformation and upgrading project was successfully accepted, and comprehensive strength continued to improve!

- Categories:News

- Author:

- Origin:

- Time of issue:2022-06-16 15:26

- Views:

(Summary description) As a key construction project in Hebei province ,our company’s relocation,transformation ans upgrading project has passed the acceptance of the expert group. The total investment of the project is 1 billion yuan,convering an area of 350 acres.The headquarters,R&D center and Marketing Department are located at NO. 1558 West Third Ring of Baoding city. The new factory is located in Shunping industrual Zone,10 kilometers away from the headqureters. Company headquarters New factory Afte the company moved to the new site, and after more than two years of process reenigineering,transformation and upgrading, technilogy level,production capacity has been greatly improved! Equipped with 3 sets of the latest painting lines and 8 sets of ventilation and dust removal systems, the company is a Grade B enterprise with environmental protection performance in Hebei Province. Painting lines Dust removal systems The final assembly plant of 25,000 square meters has an annual production capacoty of 300 various molding lines. Two machine processing plants,with 2 large floor boring and milling machines,2 large pentahedral horizontal machine centers, gantry processing center more than four meters, 11 boring and milling centers, small and medium-size CNC machine tools,46 machining centers,38 common processing equipments,and the maximum processing diameter of 5 meters sleeper and 9 other special processing equipments. Branch Plant 1 of metal processing (large processing) Gantry processing center Large floor boring and milling machine Large double-station pentahedral horizontal machine centers Branch Plant 2 of metal processing (small processing) In the heat treatment workshop, vacuum quenching equipment,horizontal and vertical surface quenching equipment represented by various types of heat treatment process equipment is complete. Heat treatment equipment Rivet and welding baranch, material cutting all by CNC, large steel pretreatment room,large annealing furance highlights the process characteristics. Material cutting by CNC Large steel pretreatment room Large annealing furance Foundary brance,15 tons, 5 tons,3 tons pre hour melting furnace,large self-harding sand production line,post-treatment line,robot grinding, to ensure the monthly output of more than 1000 tons of high –end castings. Melting furance Molding line Self-harding sand production line The company has a complete quality control system and testing equipment, is the industry’s first through ISO 9000 and other standards identified enterprises, with direct reading spectrum analyzer,ultrasonic detector, three coordinates measuring instrument and a batch of modern testing equipment. As a cloud demonstration enterprise in Hebei Province, the company has always been in fhe forefront of the industry in digital and intelligent transformation and upgrading,there are intelligent systems in operation today: intelligent office automatic system(OA),product aftermarket intelligent management system(PAM),product life cycle intelligent management system(PLM),rail transfer intelligent system(RTI), network video intelligent monitoring system(NVM), and an enterprise resource planning system under construction(ERP). Product aftermarket intelligent management system(PAM) Rrail transfer intelligent system(RTI) Network video intelligent monitoring system(NVM) 16 May. 2022 Reporter:Lijuan

Our company’s relocation,transformation and upgrading project was successfully accepted, and comprehensive strength continued to improve!

(Summary description) As a key construction project in Hebei province ,our company’s relocation,transformation ans upgrading project has passed the acceptance of the expert group.

The total investment of the project is 1 billion yuan,convering an area of 350 acres.The headquarters,R&D center and Marketing Department are located at NO. 1558 West Third Ring of Baoding city. The new factory is located in Shunping industrual Zone,10 kilometers away from the headqureters.

Company headquarters

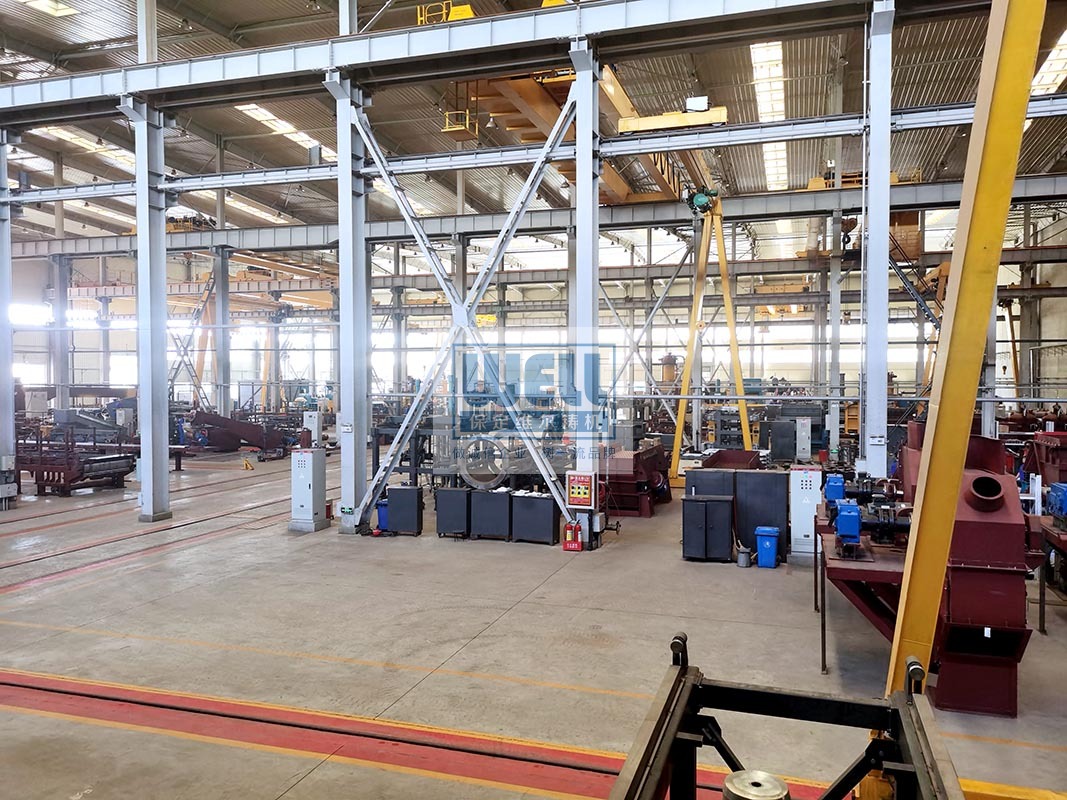

New factory

Afte the company moved to the new site, and after more than two years of process reenigineering,transformation and upgrading, technilogy level,production capacity has been greatly improved!

Equipped with 3 sets of the latest painting lines and 8 sets of ventilation and dust removal systems, the company is a Grade B enterprise with environmental protection performance in Hebei Province.

Painting lines

Dust removal systems

The final assembly plant of 25,000 square meters has an annual production capacoty of 300 various molding lines.

Two machine processing plants,with 2 large floor boring and milling machines,2 large pentahedral horizontal machine centers, gantry processing center more than four meters, 11 boring and milling centers, small and medium-size CNC machine tools,46 machining centers,38 common processing equipments,and the maximum processing diameter of 5 meters sleeper and 9 other special processing equipments.

Branch Plant 1 of metal processing (large processing)

Gantry processing center

Large floor boring and milling machine

Large double-station pentahedral horizontal machine centers

Branch Plant 2 of metal processing (small processing)

In the heat treatment workshop, vacuum quenching equipment,horizontal and vertical surface quenching equipment represented by various types of heat treatment process equipment is complete.

Heat treatment equipment

Rivet and welding baranch, material cutting all by CNC, large steel pretreatment room,large annealing furance highlights the process characteristics.

Material cutting by CNC

Large steel pretreatment room

Large annealing furance

Foundary brance,15 tons, 5 tons,3 tons pre hour melting furnace,large self-harding sand production line,post-treatment line,robot grinding, to ensure the monthly output of more than 1000 tons of high –end castings.

Melting furance

Molding line

Self-harding sand production line

The company has a complete quality control system and testing equipment, is the industry’s first through ISO 9000 and other standards identified enterprises, with direct reading spectrum analyzer,ultrasonic detector, three coordinates measuring instrument and a batch of modern testing equipment.

As a cloud demonstration enterprise in Hebei Province, the company has always been in fhe forefront of the industry in digital and intelligent transformation and upgrading,there are intelligent systems in operation today: intelligent office automatic system(OA),product aftermarket intelligent management system(PAM),product life cycle intelligent management system(PLM),rail transfer intelligent system(RTI), network video intelligent monitoring system(NVM), and an enterprise resource planning system under construction(ERP).

Product aftermarket intelligent management system(PAM)

Rrail transfer intelligent system(RTI)

Network video intelligent monitoring system(NVM)

16 May. 2022

Reporter:Lijuan

- Categories:News

- Author:

- Origin:

- Time of issue:2022-06-16 15:26

- Views:

As a key construction project in Hebei province ,our company’s relocation,transformation ans upgrading project has passed the acceptance of the expert group.

The total investment of the project is 1 billion yuan,convering an area of 350 acres.The headquarters,R&D center and Marketing Department are located at NO. 1558 West Third Ring of Baoding city. The new factory is located in Shunping industrual Zone,10 kilometers away from the headqureters.

Company headquarters

New factory

Afte the company moved to the new site, and after more than two years of process reenigineering,transformation and upgrading, technilogy level,production capacity has been greatly improved!

Equipped with 3 sets of the latest painting lines and 8 sets of ventilation and dust removal systems, the company is a Grade B enterprise with environmental protection performance in Hebei Province.

Painting lines

Dust removal systems

The final assembly plant of 25,000 square meters has an annual production capacoty of 300 various molding lines.

Two machine processing plants,with 2 large floor boring and milling machines,2 large pentahedral horizontal machine centers, gantry processing center more than four meters, 11 boring and milling centers, small and medium-size CNC machine tools,46 machining centers,38 common processing equipments,and the maximum processing diameter of 5 meters sleeper and 9 other special processing equipments.

Branch Plant 1 of metal processing (large processing)

Gantry processing center

Large floor boring and milling machine

Large double-station pentahedral horizontal machine centers

Branch Plant 2 of metal processing (small processing)

In the heat treatment workshop, vacuum quenching equipment,horizontal and vertical surface quenching equipment represented by various types of heat treatment process equipment is complete.

Heat treatment equipment

Rivet and welding baranch, material cutting all by CNC, large steel pretreatment room,large annealing furance highlights the process characteristics.

Material cutting by CNC

Large steel pretreatment room

Large annealing furance

Foundary brance,15 tons, 5 tons,3 tons pre hour melting furnace,large self-harding sand production line,post-treatment line,robot grinding, to ensure the monthly output of more than 1000 tons of high –end castings.

Melting furance

Molding line

Self-harding sand production line

The company has a complete quality control system and testing equipment, is the industry’s first through ISO 9000 and other standards identified enterprises, with direct reading spectrum analyzer,ultrasonic detector, three coordinates measuring instrument and a batch of modern testing equipment.

As a cloud demonstration enterprise in Hebei Province, the company has always been in fhe forefront of the industry in digital and intelligent transformation and upgrading,there are intelligent systems in operation today: intelligent office automatic system(OA),product aftermarket intelligent management system(PAM),product life cycle intelligent management system(PLM),heavy intelligent rail giuded vehicle system(RGV), network video intelligent monitoring system(NVM), and an enterprise resource planning system under construction(ERP).

Product aftermarket intelligent management system(PAM)

Heavy intelligent rail giuded vehicle system(RGV)

Network video intelligent monitoring system(NVM)

16 May. 2022

Reporter:Lijuan

WeChat Public

WeChat APP

Add: 1558 West Third Ring Road, Jingxiu District, Baoding, Hebei Province

Tel:0312-3209148

E-mail:xsc@baodingwell.com

QQ : 734856907

- Contact Us

- Hot-line 0312-3209048

- TOP

Baoding Well Foundry Machinery Co. , Ltd. 冀ICP备10013832号