AUTOMTIC VERTICAL FLASKLESS MOLDING LINE

AUTOMTIC VERTICAL FLASKLESS MOLDING LINE

Automatic,intelligent, and high speed molding technoiogy offers best solution for volume production of small and medium castings

Main characteristics

●Vertical parting, flaskless, high speed, automatic, sand pre-compaction, hydraulic compaction molding, high productivity, high precision casting size, energy conservation and environmental protection.

●Intelligent control, proportional control and other mechatronics engineering technology and standard hydraulic and pneumatic control devices, using PLC, position detection, pressure sensing, touch screen and other imported components.

●The man-machine interface, automatic and stable operation of the process, dynamic input/output animation monitoring, fault diagnosis and alarm functions are realized. Various technical parameters of the machine can be adjusted and set on the computer screen. It can be controlled remotely.

●In intelligent control, mechatronics engineering level, reliability of equipment operation, wear resistance of components and meet the requirements of closed mold synchronous transport, mechanical core, synchronous cooling, automatic sand feeding, and other sets of functions, standardization level and maintainability.

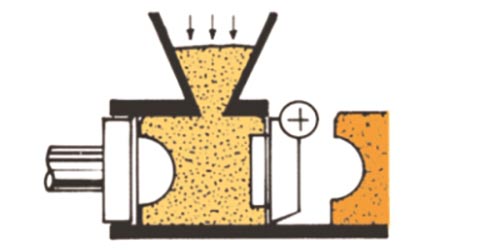

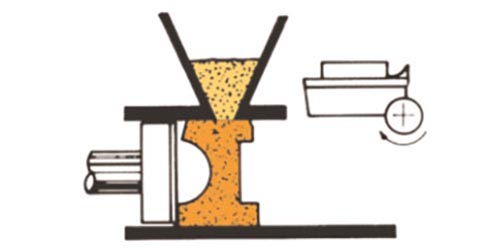

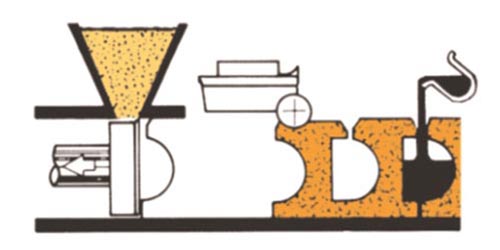

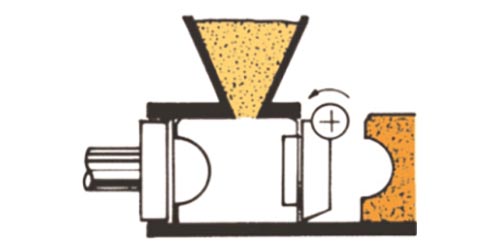

Moulding technology schematic diagram

Shot sand to the colsed cavity

main cylinder push extrusion molding

the swing reverse plate separated from the mold

push remove the sand mold from the mold

the positive pressure plate is separateed from the sand mold

closed the molding cavity

Main Specifications and technical parameters

| mold | ZZ416AF | ZZ416BF | ZZ417AF | ZZ417BF | ZZ417CF | ZZ417DF | ZZ418YF | ZZ418AF | ZZ418BF/BD | |

| sand mold size | width(mm) | 600 | 650 | 700 | 750 | 700 | 750 | 800 | 800 | 850 |

| height(mm) | 480 | 535 | 535 | 535 | 600 | 600 | 600 | 600 | 650 | |

| thickness(mm) | 130~390 | 130~390 | 130~390 | 130~390 | 130~390 | 130~390 | 130~380 | 150~500 | 150~500 | |

| mold speed M/H | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 350 | 350 | |

| mold | ZZ419AF | ZZ419BF | ZZ419XF | ZZ419YF | ZZ4110AF | ZZ4110BF | ZZ4111AF | ZZ4112AF | ZZ4113AF | |

| sand mold size | width(mm) | 900 | 900 | 950 | 950 | 1000 | 1000 | 1100 | 1200 | 1300 |

| height(mm) | 650 | 700 | 700 | 800 | 800 | 900 | 1050 | 1100 | 1100 | |

| thickness(mm) | 150~500 | 150~500 | 200~650 | 200~650 | 200~650 | 200~400 | 200~350 | 250~350 | 250~500 | |

| mold speed M/H | 330 | 330 | 280 | 280 | 280 | 200 | 200 | 200 | 200 | |

Main components

The molding line is mainly composed of molding machine and sand feeder, horizontal core setter machine (optional) , automatic synchronous mold clamping/pull type mold conveyor(AMC/PMC), synchronous cooling conveyor(SBC) and other auxiliary machines.

Molding machine, using the principle of shooting compact molding, while complete of the mold, closure, push-type work.

Rapid template replacement device.

Horizontal core setter machine, to achieve rapid and accurate on-line synchronous core down (optional) .

Automatic synchronous mold clamping/pull type mold conveyor(AMC/PMC), to complete the casting convey during the pouring cooling process synchronous with the main molding machine. Clamping conveying is suitable for small sand mold conveying, which can effectively improve the conveying accuracy of large sand mold and reduce equipment wear.

Synchronous Belt Cooler, according to the difference time of the casting cooling, and synchronous with clamping/holding conveyor, to extend the sand conveying time.

ZZ4113AF molding machine maximum sand size 1300X1100X500MM

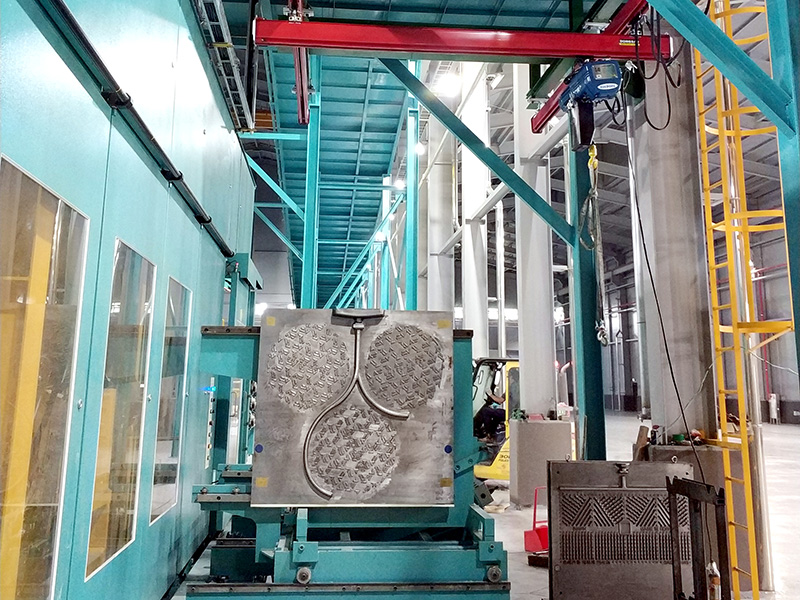

XX418AF assembly site

WeChat Public

WeChat APP

Add: 1558 West Third Ring Road, Jingxiu District, Baoding, Hebei Province

Tel:0312-3209148

E-mail:xsc@baodingwell.com

QQ : 734856907

- Contact Us

- Hot-line 0312-3209048

- TOP

Baoding Well Foundry Machinery Co. , Ltd. 冀ICP备10013832号