AUTOMATIC HORIZONTAL MULTI-PISTON MOLDING LINE

AUTOMATIC HORIZONTAL MULTI-PISTON MOLDING LINE

The most advanced molding technology offers the best solution for volume production of high quality castings.

Main characteristics

Using air blowing precompaction and multi-contact high-pressure compaction molding technology, high sand mold hardness, compactness uniformity, high box closure precision, high casting precision, high yield. The average hardness of sand mold is 90-95. Hydraulic multi-contact compaction, the compaction ratio can be adjusted in different zones, up to 1.5 Mpa.

The control System consists of an engineer station, an operator station and a number of auxiliary stations, each equipped with a man-machine interface, using industrial computer, CNC, PLC field bus, servo technology, proportional valve, frequency control, automatic detection, computer monitoring and other advanced technology.

The whole line adopts the principle of combining electric, hydraulic and pneumatic transmission, and the key components adopt international brand products to ensure the smooth and reliable operation of the production line.

Full-line automatic high-efficiency, high casting precision, clean working environment, is the most advanced molding production line. Has been widely used in automotive castings and other gray iron, ductile iron, cast steel and other high-grade casting mass production.

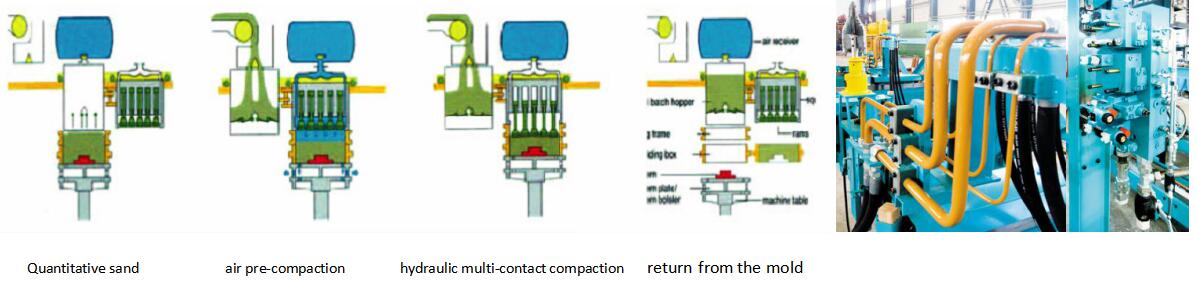

Moulding technology schematic diagram

Main specifications and technical parameters

According to the customer product specifications, personalized design

|

Parameter/model |

YJZ66 |

YJZ77 |

YJZ97 |

YJZ98 |

YJZ108 |

YJZ1010 |

|

Flask inner size(mm) |

680x580x200/220 |

700x700x350/250 |

900x700x250/250 |

900x800x350/300 |

1000x800x350/320 |

1000x1000x350/250 |

|

productivity(box/h) |

120 |

110 |

100 |

100 |

100 |

100 |

|

Parameter/model |

YJZ128 |

YJZ129 |

YJZ138 |

YJZ139 |

YJZ188 |

YJZ19515 |

|

Flask inner size(mm) |

1200x800x350/250 |

1200x900x350/350 |

1300X800x300/300 |

1300x900x350/300 |

1850x800X380/320 |

1950x1500x550/450 |

|

productivity(box/h) |

100 |

100 |

90 |

90 |

40 |

40 |

The static pressure molding machine adopts the compaction technology of air flow precompaction + hydraulic multi-contact compaction, template back compaction + hydraulic multi-contact compaction, which further improves the hardness and compaction uniformity of sand mold parting surface and improves the casting precision.

Static pressure molding line for automobile cylinder body

Major components of the molding line

The molding line is mainly composed of molding, core closing box, pouring cooling, sand shakeout and other sections. Including static pressure molding machine, auxiliaries, casting conveyor, electronic control hydraulic system and flask, plate frame and other process equipment.

The static pressure molding machine mainly includes lifting worktable, blowing precompaction device, multi-contact compaction device, shutter type sand adding device, plate rotating device, etc. .to complete sand feeding rationally,molding,stripping and plate exchange working procedures.

The main auxiliary machines of Molding Line are flask poking machine, flask dividing machine, flask lifting machine, flask dropping machine, flask shifting machine, flask cleaning machine, flask closing machine, flask tightening and flask loosening device, air-drilling device, gate-milling device, etc. .to complete the whole line of auxiliary procedure.

The casting conveyor mainly has the transfer vehicle, the transmission push rod, the buffer push rod, the trolley and the localization device and so on, uses in the casting mold automatic transportation.

The Control System consists of an engineer station, an operating master station and a number of computer-side stations with man-machine interface. It adopts advanced technologies such as industrial control computer, numerical control, PLC field bus, Servo, proportional valve, variable frequency speed regulation, automatic detection, computer monitoring, etc. , the key components adopt international brand products.

1950×1500×550/450static molding line is used in machine tool casting production

Automatic horizontal multi-piston molding line

drill air hole-mill pouring riser-drop flask-core setter section Core setter Section of 1950 ~ 1500 ~ 550/450 static pressure

On-line pouring of pouring machine

off-line monitoring and control in static pressure molding line production-on-line automatic pouring

core setter machine of cylinder Block static pressure molding line

flask closure machine of static pressure molding line

WeChat Public

WeChat APP

Add: 1558 West Third Ring Road, Jingxiu District, Baoding, Hebei Province

Tel:0312-3209148

E-mail:xsc@baodingwell.com

QQ : 734856907

- Contact Us

- Hot-line 0312-3209048

- TOP

Baoding Well Foundry Machinery Co. , Ltd. 冀ICP备10013832号